Why It’s Important To Automate Your CNC Machines

Manufacturers are under constant pressure to produce more parts in less time while maintaining tight tolerances. Labor challenges, rising costs, and increasing complexity only add to the strain. That’s why many shops are reassessing workflows and asking critical questions about the importance of automating CNC machines. Automation is no longer optional for competitive operations—it is a strategic investment in precision, reliability, and long-term growth.

Whether you operate a high-mix job shop or rely on a specialized die/mold CNC machine for intricate cavity work, automation can significantly enhance performance. It strengthens process control, reduces variability, and allows your team to focus on higher-value tasks. When implemented correctly, automation transforms your machine tools into consistent, production-ready systems capable of running with minimal interruption.

Automation Improves Uptime and Throughput

Unplanned downtime is one of the most expensive issues in manufacturing. A machine that sits idle because an operator is unavailable or a process stalls represents lost revenue. Automation helps teams eliminate these gaps by keeping production moving even when manual intervention is limited.

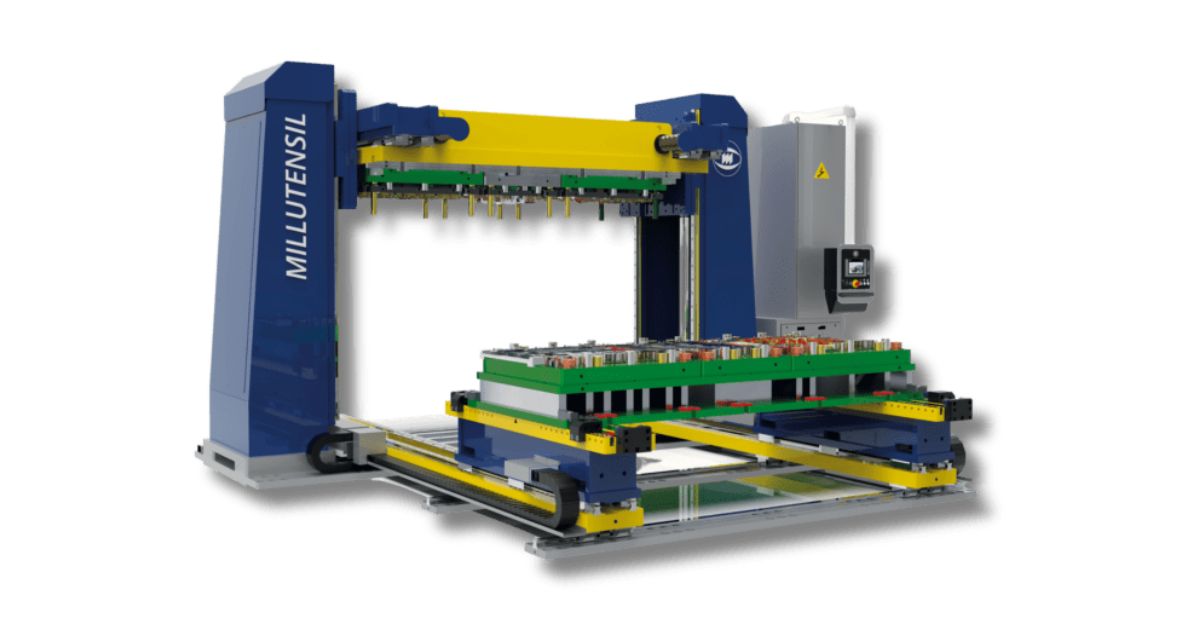

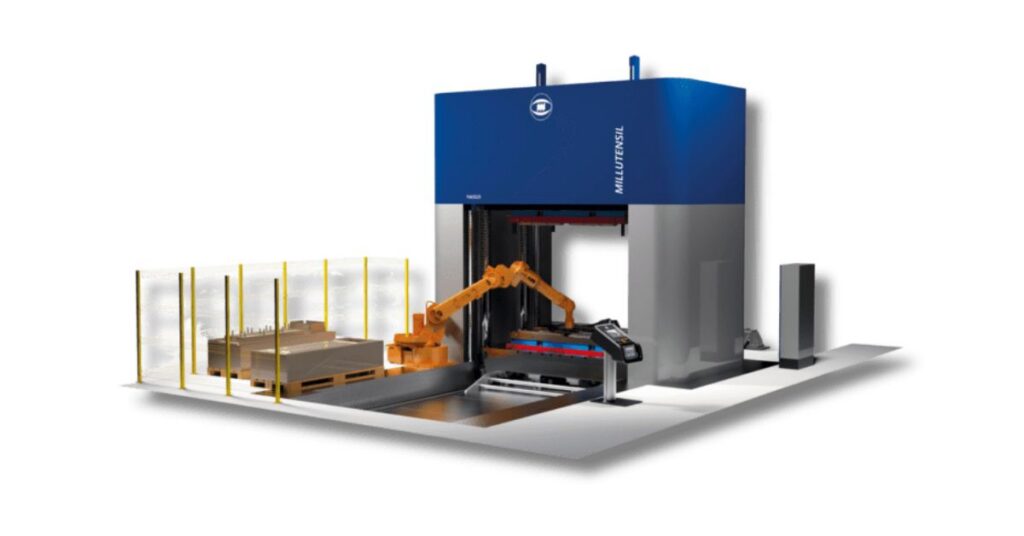

With automated pallet systems, robotic part handling, or tool monitoring systems, machines can continue operating through shift changes or during lights-out hours. This increases spindle uptime and ensures your investment delivers measurable returns.

Higher uptime leads to:

- Greater part output per shift

- Improved machine utilization rates

- More predictable production schedules

For shops running a die/mold CNC machine, uninterrupted machining is critical. Mold and die work often involves long cycle times and detailed finishing passes. Automation ensures those processes continue without disruption, preserving accuracy and efficiency.

Consistency Drives Quality

Precision machining demands repeatability. Even the smallest deviation can impact part fit, surface finish, or dimensional accuracy. Automation reduces variability by minimizing manual handling and standardizing process execution.

With greater consistency in parts loading, cramping, and transfer, you reduce the opportunity for human error. Tool life monitoring and automated probing systems further enhance reliability by detecting wear or dimensional drift before scrap occurs.

This is especially important for die and mold applications, where tolerances are tight and rework can be costly. A properly integrated die/mold CNC machine equipped with automation ensures consistent cavity depth, surface integrity, and alignment across production runs.

Quality comes down to delivering repeatable performance shift after shift. Automation reinforces that standard.

Addressing Labor Challenges

Many manufacturers face skilled labor shortages. Finding experienced machinists is increasingly difficult, and training new operators takes time. Automation helps bridge that gap without compromising output.

Instead of dedicating skilled personnel to repetitive loading tasks, shops can reassign talent to programming, process optimization, and quality control. This increases operational efficiency and supports workforce development.

Automation also improves workplace safety by reducing manual lifting and repetitive motion. Robots and pallet changers handle heavy workpieces more reliably than manual systems, lowering injury risk. By supporting your workforce rather than replacing it, automation strengthens long-term operational stability.

Maximizing Single-Setup Machining

One of the most effective ways to improve efficiency is to complete more operations in a single setup. Multi-axis machines and advanced tooling allow complex parts to be machined with fewer repositioning steps. Automation complements this approach.

Automated pallet systems and fixture management ensure that once a part is secured, it can move seamlessly through machining cycles without re-clamping. This reduces geometric inaccuracies and improves part integrity.

For mold and die applications, where multiple contours and surfaces must align precisely, combining automation with a high-performance die/mold CNC machine provides measurable advantages. The ability to maintain rigidity and repeatability throughout extended cycles protects both the part and the machine.

Reducing setups not only saves time but also protects dimensional precision.

Supporting Lights-Out Manufacturing

Lights-out manufacturing refers to operating CNC machines without direct supervision, often overnight. While not every shop will adopt full lights-out production, many benefit from partial automation that extends machining beyond staffed hours.

To achieve reliable lights-out capability, you need:

- Stable machine platforms with proven rigidity

- Automated part handling or pallet systems

- Tool monitoring and failure detection

A robust machine foundation is essential. Automation does not compensate for poor construction or lack of rigidity. Instead, it amplifies the performance of a well-built system.

Reducing Long-Term Operating Costs

Automation requires upfront investment, but the long-term savings are significant. Increased uptime, reduced scrap, and improved labor allocation all contribute to lower cost per part.

In competitive industries such as aerospace, automotive, medical, and energy, consistent output and reliability determine profitability. A machine breakdown during peak production can cost far more than the initial investment in automation.

Over time, automated systems can:

- Stabilize production output

- Reduce part handling damage

- Improve forecasting and scheduling

When buyers evaluate equipment, purchase price should never be the only factor. Reliability, rigidity, and long-term durability determine the total cost of ownership. Automation enhances those strengths when integrated with high-quality CNC machines.

Enhancing Data and Process Visibility

Modern automation systems often integrate with digital monitoring platforms. These tools provide real-time performance data, helping managers identify bottlenecks and optimize workflows.

With actionable data, shops can:

- Track spindle utilization

- Monitor tool wear trends

- Analyze cycle time consistency

Better visibility supports informed decision-making. Instead of reacting to problems after they occur, teams can proactively adjust processes.

Automation Protects Machine Investment

CNC machines are long-term capital assets. Protecting that investment is critical. Automation reduces unnecessary stress caused by improper loading, inconsistent clamping, or abrupt process interruptions.

When machines operate under stable, controlled conditions, wear patterns become predictable. This extends service life and preserves accuracy over time.

Durability and rigidity are foundational to reliable machining. Automation supports those characteristics by ensuring the machine operates within optimal parameters.

Over years of operation, the combined benefits of precision engineering and automation result in sustained productivity and performance.

Preparing for Future Growth

Manufacturing demands continue to evolve. Part complexity increases, lead times shrink, and quality standards tighten. Automation prepares your operation for those challenges.

Instead of reacting to customer demands, automated systems allow you to scale production strategically. Additional shifts, expanded capacity, and diversified part portfolios become more achievable with standardized and repeatable processes.

For companies investing in advanced die/mold CNC machine platforms, automation creates the flexibility needed to meet both short-term contracts and long-term growth objectives.

Future-ready operations are built on precision, reliability, and adaptability.

Improve Your Processes

Manufacturing success depends on consistency, uptime, and long-term performance. Automation strengthens each of these pillars by reducing variability, improving throughput, and supporting skilled labor. As competition increases, understanding the importance of automating CNC machines becomes essential for maintaining profitability and quality standards. When paired with a precision-engineered die/mold CNC machine, automation transforms individual machine tools into fully integrated production systems.

If you are ready to improve throughput and maintain uncompromising precision, explore the YCM Alliance’s advanced die/mold CNC machines and discover how integrated automation can elevate your production performance.