Choosing the Right Machine for the Job

Application Type

Brand

Die Mold Machining

You can count on YCM Alliance partners for experience and expertise in die mold machining applications. All YCM Alliance partners share the same process approach to your business, ensuring best-in-class machining solutions. Together, we deliver high-quality machining solutions to help grow your business.

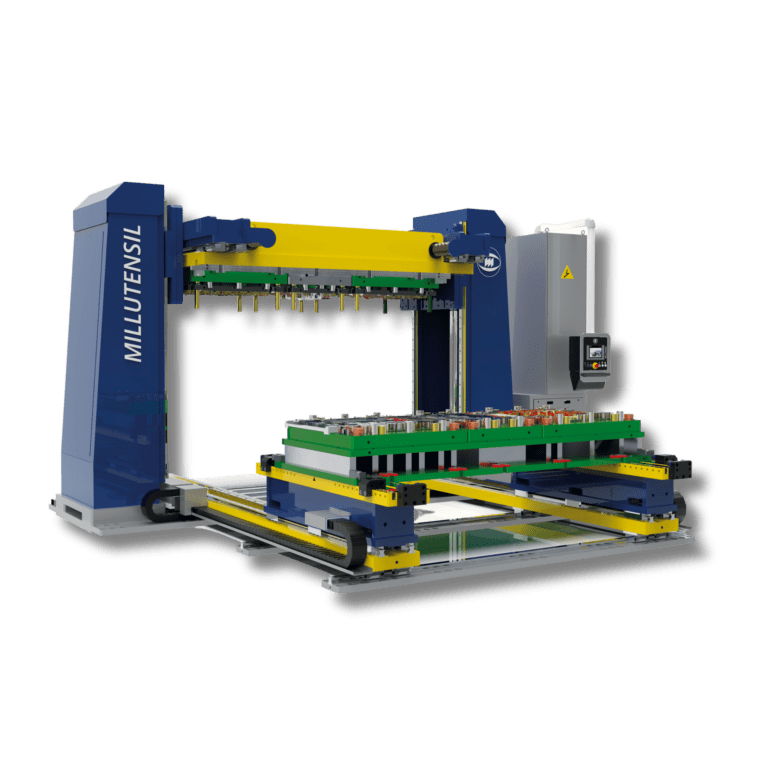

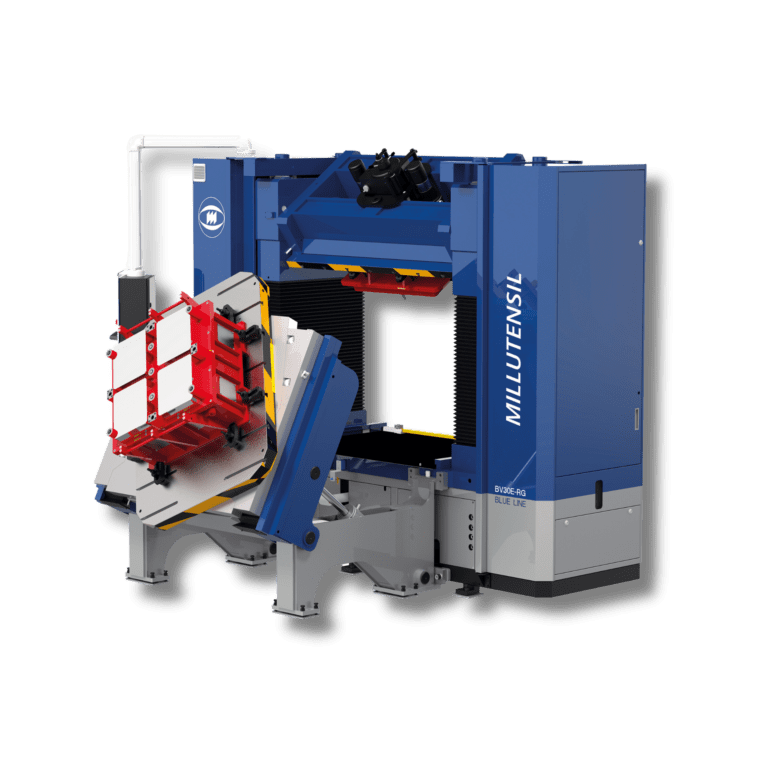

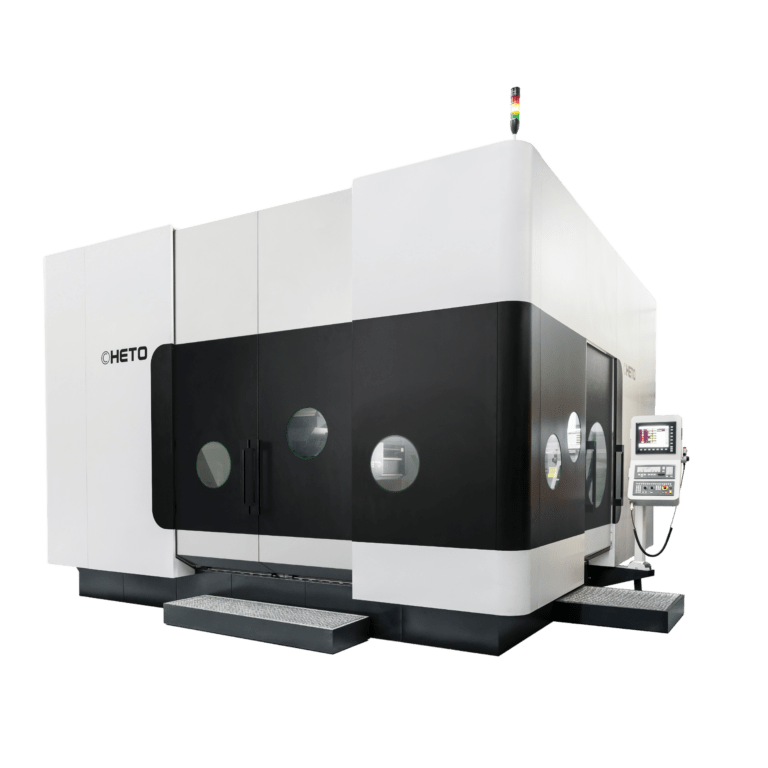

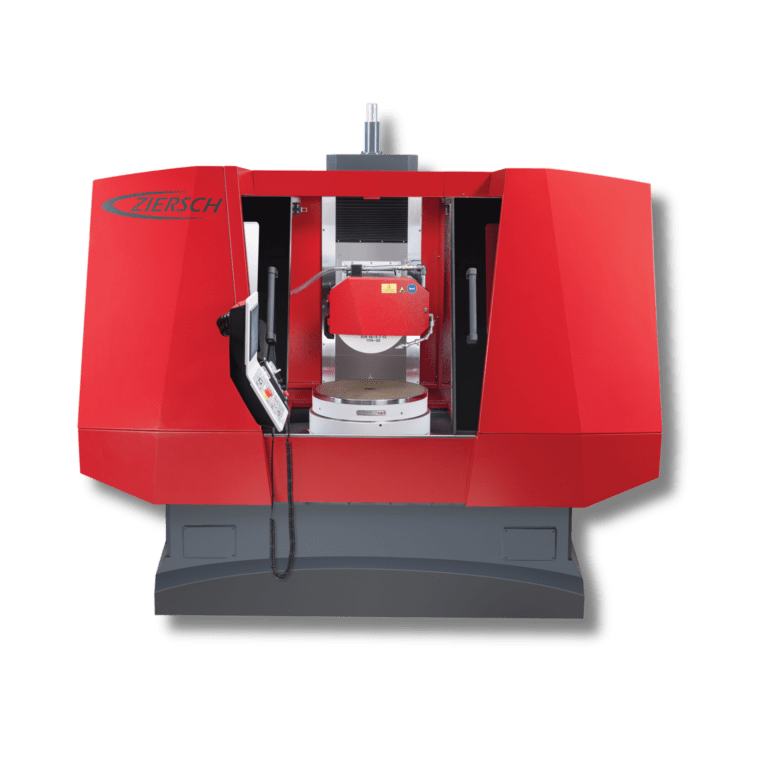

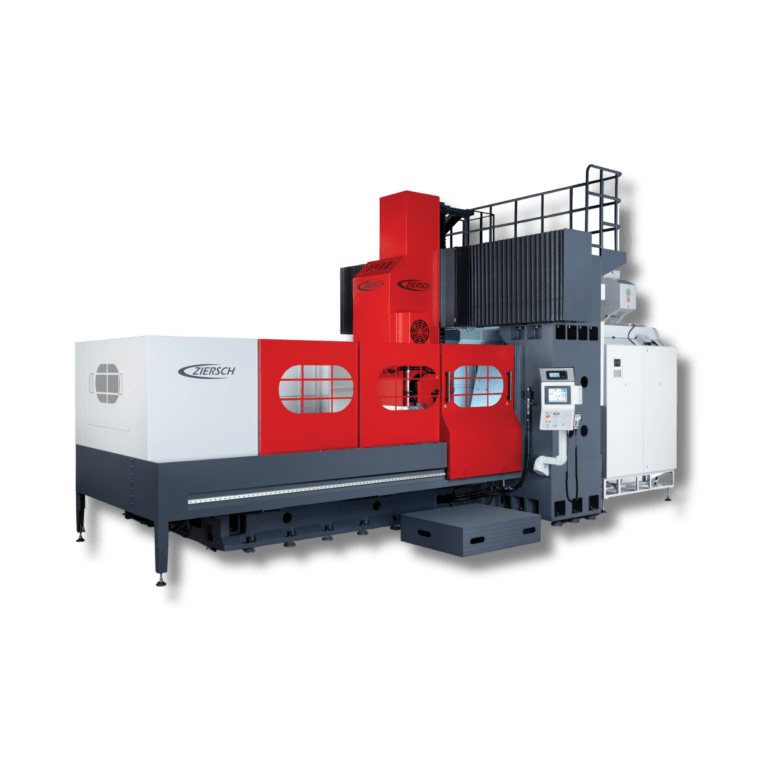

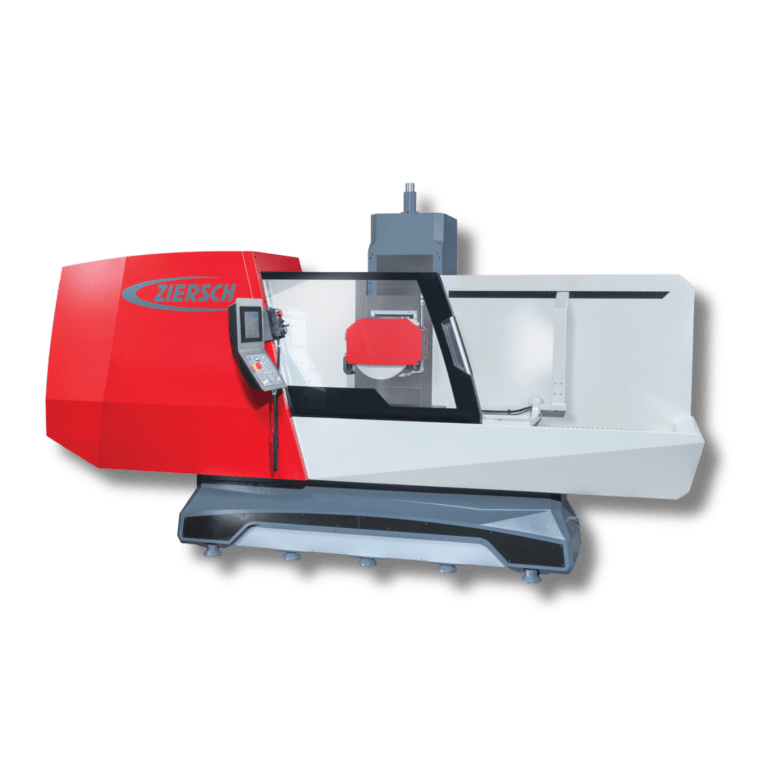

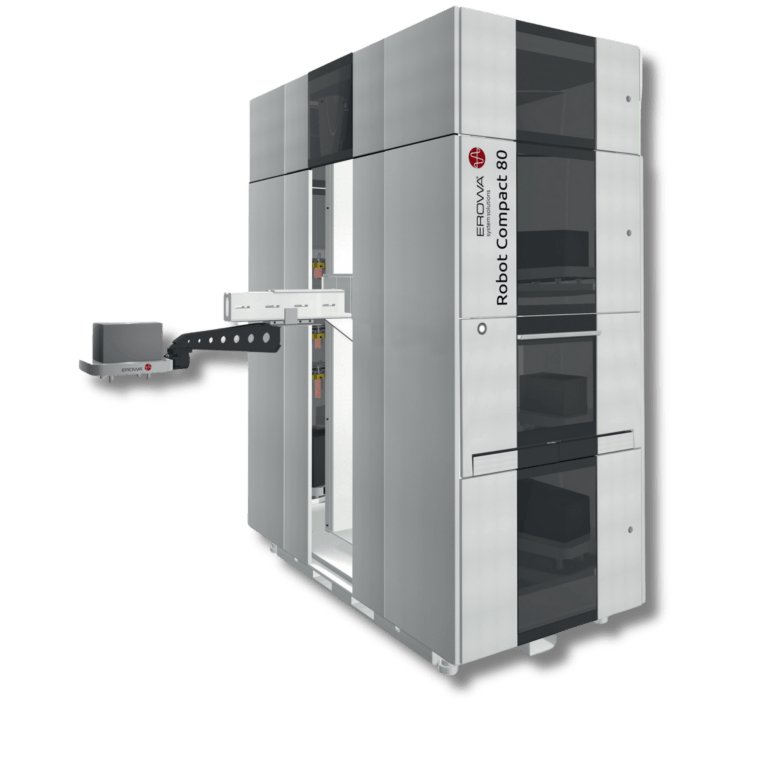

The YCM Alliance delivers machining solutions with the speed, accuracy, flexibility, and surface finishes die and mold makers require. Milling, turning, boring, drilling, large format machining, wire cut EDM, and sinker EDM machines are all part of our Die/Mold solutions.

With advanced CNC machining for die and mold industry applications, YCM Alliance helps manufacturers reduce cycle times while achieving superior surface finishes. We engineer each CNC machine for mold making for precision and longevity to ensure complex geometries are produced with repeatable accuracy.

Whether you require an all-purpose solution or a specialized die mold CNC machine, our technology and expert support deliver the consistency and performance needed for modern die mold machining operations. This commitment to quality drives long-term success in demanding industries.

Find the right solutions for your business with YCM Alliance.