The Ultimate Guide to Cylindrical Grinding Machines

Cylindrical grinding machines are essential tools in precision manufacturing, enabling industries to achieve exceptional accuracy and superior surface finishes on cylindrical components. Use our guide to cylindrical grinding machines to explore how these machines work, their applications across industries, and the critical factors to consider before investing in one. By the end, you’ll have the knowledge needed to select the right cylindrical grinder for your specific requirements.

What Is Cylindrical Grinding?

Cylindrical grinding is a precision machining process that removes material from cylindrical workpieces to achieve exact dimensions and smooth surface finishes. The process uses an abrasive grinding wheel that rotates at high speed while the workpiece rotates on a separate axis. As these two surfaces interact, material removal occurs in controlled increments.

This process excels at producing parts with tight tolerances, typically within 0.0001 inches, and surface finishes that can reach Ra values below 8 microinches. Such precision makes cylindrical grinding indispensable for components requiring exact roundness, concentricity, and dimensional accuracy.

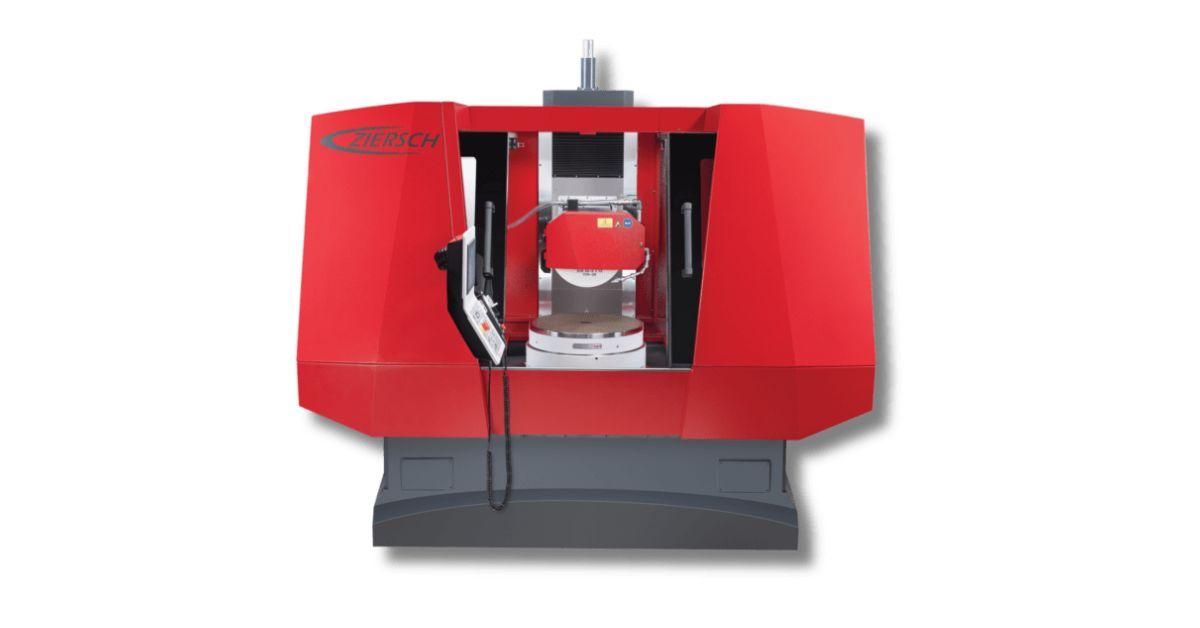

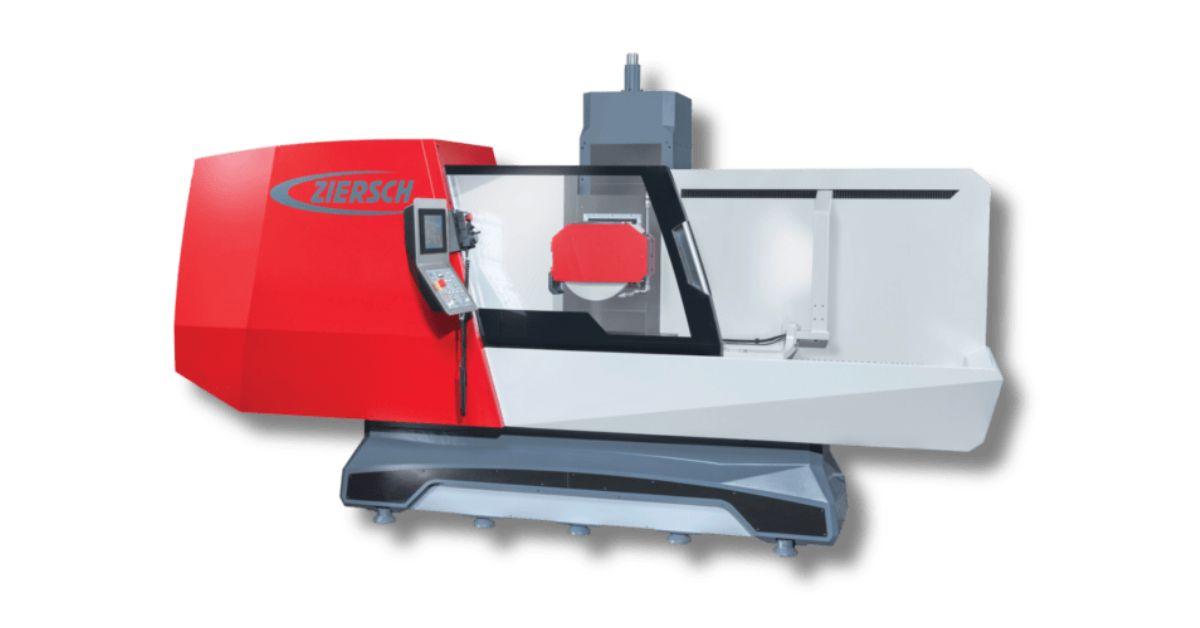

Basic Components of a Cylindrical Grinding Machine

Cylindrical grinding machines consist of several integrated systems working together to deliver precision results:

Wheelhead: The wheelhead houses the grinding wheel and its drive motor. It provides the rotational motion necessary for material removal and typically includes mechanisms for precise positioning and dressing the grinding wheel to maintain its cutting efficiency.

Workhead: The workhead holds and rotates the workpiece at controlled speeds. Modern workheads feature variable speed capabilities, allowing operators to optimize cutting conditions for different materials and geometries. Precision bearings ensure smooth rotation without vibration that could compromise surface quality.

Tailstock: The tailstock supports the opposite end of long workpieces, preventing deflection during grinding. It applies adjustable pressure to maintain workpiece stability while accommodating thermal expansion and contraction during the grinding process.

Machine base: The machine base provides the structural foundation for all components. Heavy cast iron construction ensures rigidity that resists cutting forces and vibrations. Precision slideways machined into the base allow for accurate positioning of the wheelhead and workhead.

Control system: Modern cylindrical grinders feature CNC control systems that automate the grinding process. These systems manage wheel positioning, feed rates, and dress cycles while providing real-time monitoring of grinding conditions. Touch screen interfaces simplify operation and programming.

The Cylindrical Grinding Process

Cylindrical grinding begins with securing the workpiece between the workhead and tailstock. Operators establish the datum reference points and input the target dimensions into the control system. The grinding wheel then approaches the workpiece surface while both rotate.

Material removal occurs through the interaction between the abrasive grains on the wheel surface and the workpiece material. The process generates significant heat, requiring flood coolant systems to prevent thermal damage and flush away grinding swarf. Multiple passes gradually reduce the workpiece diameter until reaching the target dimension.

Throughout the process, the control system monitors cutting forces and adjusts parameters to maintain optimal grinding conditions. Automatic dress cycles restore the grinding wheel’s cutting efficiency by exposing fresh abrasive grains and maintaining the wheel’s geometric form.

Types of Cylindrical Grinding

Different grinding approaches address specific manufacturing requirements.

Outer Diameter (OD) Grinding

OD grinding shapes the external surface of cylindrical components. The grinding wheel traverses along the workpiece length while gradually approaching the workpiece centerline. This method produces shafts, pins, and other externally ground components with excellent surface finish and dimensional accuracy.

Inner Diameter (ID) Grinding

ID grinding machines internal cylindrical surfaces, such as bearing bores and hydraulic cylinder walls. Specialized grinding wheels mounted on extended spindles reach into the workpiece interior. The process demands careful attention to wheel balance and coolant delivery to prevent chatter and ensure surface quality.

Angle Grinding

Angle grinding creates tapered surfaces and shoulders on cylindrical parts. The wheelhead swivels to the required angle, allowing the grinding wheel to follow the specified taper. This capability proves essential for producing components like taper roller bearing cones and valve stems.

Plunge Grinding

Plunge grinding feeds the grinding wheel radially into the workpiece without longitudinal traverse. This approach efficiently produces specific diameters and contours, particularly when combined with formed grinding wheels that match the desired profile. Plunge grinding excels at high-volume production of identical parts.

Applications of Cylindrical Grinding

High-Precision Industries

Industries requiring extreme accuracy rely heavily on cylindrical grinding. Components in these sectors often function in demanding environments where dimensional precision directly impacts performance and safety. Cylindrical grinders consistently deliver the micron-level accuracy these applications demand.

Precision manufacturing encompasses applications from optical instrument components to hydraulic system parts. Each application benefits from the superior surface finishes and exact concentricity that cylindrical grinding provides.

Automotive Industry

Automotive manufacturers depend on cylindrical grinding for critical powertrain components. Crankshafts require precise journal dimensions and surface finishes to ensure proper bearing performance and engine longevity. Camshafts demand exact lobe profiles and bearing surfaces that cylindrical grinding efficiently produces.

Transmission shafts, drive shafts, and CV joint components all benefit from the process. The automotive industry’s high-volume production requirements align well with the automation capabilities of modern CNC cylindrical grinders.

Aerospace Industry

Aerospace applications demand the highest quality standards and traceability. Cylindrical grinding produces landing gear components, turbine shafts, and hydraulic actuator parts that meet stringent aerospace specifications. The process handles exotic materials like titanium alloys and nickel-based superalloys commonly used in aerospace applications.

Quality documentation and process control inherent in CNC cylindrical grinding systems satisfy aerospace quality management requirements. The YCM Alliance’s cylindrical grinders provide the reliability and precision necessary for these critical applications.

Medical Device Manufacturing

Medical device manufacturers require components with exceptional surface finishes and biocompatibility. Surgical instrument shafts, orthopedic implant components, and dental tool parts all benefit from cylindrical grinding’s capabilities. The process produces parts that meet FDA requirements and international medical device standards.

Material considerations prove critical in medical applications. Cylindrical grinders effectively machine stainless steel, titanium, and cobalt-chrome alloys while maintaining the surface integrity essential for medical implants.

Advantages of Cylindrical Grinding

High Precision and Accuracy

Cylindrical grinding achieves tolerances that other machining processes cannot match. The rigid machine structure, precise linear motion systems, and automated controls combine to deliver consistent accuracy across production runs. Part-to-part variation remains minimal, reducing scrap rates and ensuring interchangeability.

Geometric accuracy extends beyond simple diameter control. Cylindrical grinders maintain excellent roundness, straightness, and concentricity. These geometric characteristics prove crucial for components in high-speed rotating applications.

Superior Surface Finish

Surface finish quality directly impacts component performance and longevity. Cylindrical grinding produces mirror-like finishes that reduce friction, improve wear resistance, and enhance fatigue life. Controlled cutting conditions and proper coolant application minimize surface defects like grinding burns and microcracks.

The process allows optimization of surface finish parameters independently from dimensional accuracy. This flexibility enables manufacturers to achieve exactly the surface characteristics their applications require.

Versatility

Modern cylindrical grinders handle diverse workpiece geometries and materials. From small precision pins to large industrial rolls, these machines adapt to varying production requirements. The same machine can perform OD grinding, ID grinding, and angle grinding operations with appropriate tooling changes.

Material versatility extends from soft aluminum alloys to hardened tool steels and ceramics. This broad capability reduces the need for multiple specialized machines in the production facility.

Automation Capabilities

CNC control systems enable lights-out manufacturing with minimal operator intervention. Automated loading systems, in-process gauging, and adaptive control maintain quality while maximizing machine utilization. Production consistency improves as human error factors decrease.

Integration with manufacturing execution systems provides real-time production data and quality metrics. This connectivity supports lean manufacturing initiatives and predictive maintenance programs.

Factors To Consider Before Buying a Cylindrical Grinder

Material Compatibility

Material characteristics significantly influence grinder selection. Soft materials like aluminum require different grinding parameters than hardened steels. Abrasive materials such as composites demand specialized grinding wheels and cooling strategies.

Consider both current production requirements and future material needs. Selecting a machine capable of handling harder materials provides flexibility for expanding your product offerings.

Precision and Accuracy

Specify the tightest tolerances your applications require. Machine specifications should exceed your requirements by a comfortable margin to account for normal variations in operating conditions. Remember that advertised specifications represent optimal conditions with new components.

Thermal stability also has the potential to significantly affect accuracy. Machines with temperature-controlled components and thermal compensation systems maintain accuracy across varying shop floor conditions.

Size and Capacity

Workpiece dimensions dictate minimum machine capacity requirements. Maximum grinding diameter, maximum grinding length, and maximum workpiece weight define the machine’s capability. Allow margin for potential future requirements when sizing your equipment.

Consider how workpiece dimensions affect cycle times. Larger machines may offer capacity you need but operate less efficiently on smaller parts. Multiple machines optimized for different size ranges often prove more cost-effective than a single large machine.

Control System

Control system capabilities directly impact productivity and ease of operation. Evaluate programming interfaces, conversational programming features, and simulation capabilities. Systems with extensive canned cycles simplify setup for common operations.

Integration capabilities matter for modern manufacturing environments. Network connectivity, data logging, and compatibility with shop floor management systems support continuous improvement initiatives.

Maintenance and Support

Maintenance requirements vary significantly between machine designs. Some systems require daily lubrication, while others feature automatic lubrication systems. Assess maintenance complexity against your staff’s capabilities.

Supplier support quality proves crucial for maximizing equipment uptime. Evaluate response time commitments, parts availability, and technical expertise. Local service presence reduces downtime when issues arise. Strong supplier partnerships ensure long-term success with your equipment investment.

Precision Within Reach

Cylindrical grinding machines represent powerful tools for achieving exceptional accuracy and surface quality in manufacturing operations. By understanding the fundamentals of cylindrical grinding, its diverse applications, and the key factors affecting equipment selection, you can make informed decisions that align with your production requirements.

Whether you’re entering high-precision manufacturing or upgrading existing capabilities, use our guide to cylindrical grinding machines to evaluate your needs systematically. Consider material requirements, precision specifications, production volumes, and support availability as you select equipment.

Ready to explore how cylindrical grinding can enhance your manufacturing capabilities? Contact YCM Alliance to discuss your specific requirements and discover solutions tailored to your applications. Our team brings decades of experience helping manufacturers achieve their precision goals with reliable, high-performance grinding equipment.