Why Precision Machining Is Important for the Medical Sector

In the medical world, there is no room for error. Lives often depend on the quality and reliability of medical devices. This is why the manufacturing process behind these tools is so critical. Every component must be perfect, from surgical instruments to complex implants.

At the YCM Alliance, we understand the immense responsibility that comes with this, and we believe that precision machining has an undebatable importance in the medical sector. To us, it is the foundation of modern healthcare innovation and patient safety.

The Role of Precision in Medical Devices

Medical devices range from simple tools to highly complex electronic equipment. Many of these items have parts that are incredibly small and detailed. Precision machining is the process used to create these components. It involves using computer-controlled machines to remove material from a workpiece. The result is a part made to exact specifications, often with tolerances measured in micrometers. This level of accuracy is not just a preference; it is a strict requirement.

Surgical Instruments and Tools

Surgeons rely on their instruments to perform delicate procedures. These tools must be strong, durable, and perfectly formed. Whether it’s a scalpel, forceps, or bone screw, each tool must adhere to specific shape, weight, and balance requirements. Precision machining creates instruments that feel like an extension of the surgeon’s hand.

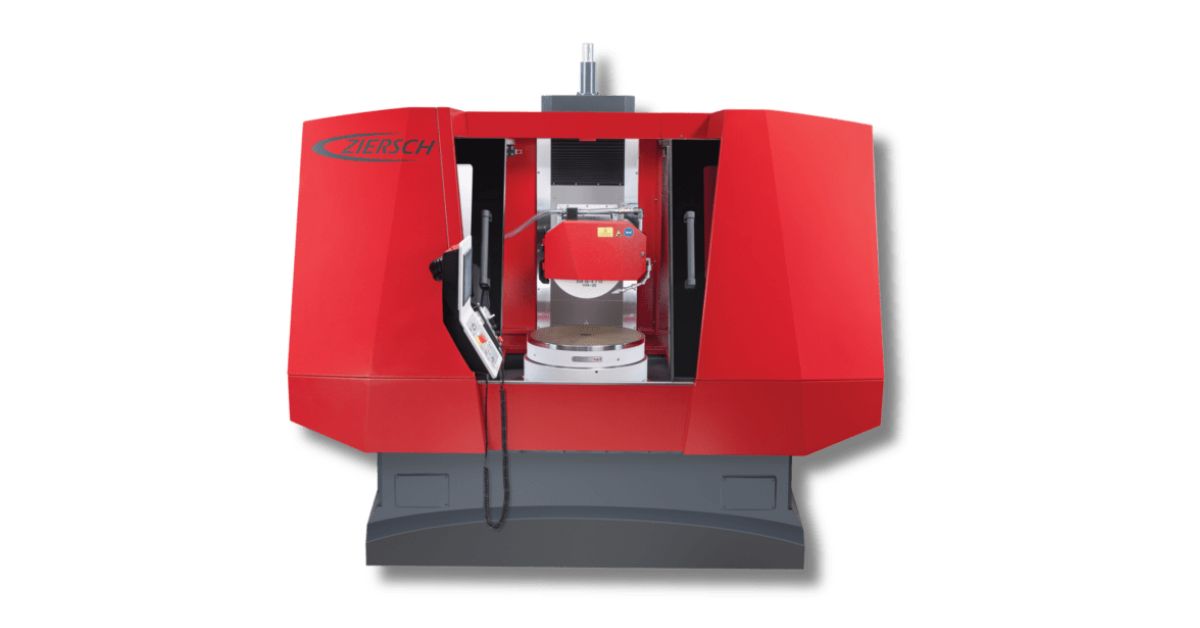

The materials used, like stainless steel and titanium, are tough. Machining them requires powerful and rigid equipment. Our machines provide the stability needed to cut these materials with flawless accuracy, ensuring every instrument meets the highest standards for performance and safety.

Medical Implants and Prosthetics

Implants such as hip replacements, spinal fusions, and dental implants must fit a patient’s body perfectly. A poor fit can lead to pain, rejection, or the need for revision surgeries. Precision machining allows for the creation of custom implants based on a patient’s unique anatomy. Using data from MRI or CT scans, machines can craft a part that is an exact match. This customization improves patient comfort and the long-term success of the implant.

Prosthetics also benefit greatly from this technology. The complex joints and moving parts require components made with extreme accuracy to allow for smooth, natural movements. With high-precision machining solutions, manufacturers can build artificial limbs that are lighter, stronger, and more functional.

Materials and Biocompatibility

The materials used in medical devices are just as important as their design. They must be biocompatible, meaning they will not cause a negative reaction inside the human body. Common materials include medical-grade stainless steel, titanium alloys, cobalt-chrome, and special plastics like PEEK. These materials are often difficult to work with, requiring machines that are both powerful and incredibly precise.

Machining Challenging Materials

Titanium, for example, is very strong, but machining this material also generates a lot of heat. This excess heat can warp the material and wear out the cutting tools. A high-quality CNC machine is able to handle these challenges. It has a rigid structure that absorbs vibrations, leading to a smoother surface finish, and uses advanced cooling systems to prevent overheating and protect both the material and the machine.

The quality of the machine directly impacts the final product. A less rigid or reliable machine might struggle with these materials. This can result in parts that are out of tolerance or have poor surface finishes. In the medical field, such imperfections are unacceptable. They could create points of weakness or areas where bacteria can grow. Our focus on quality ensures our machines can handle the toughest materials with ease.

Meeting Strict Regulatory Standards

The medical device industry is one of the most heavily regulated in the world. Agencies like the Food and Drug Administration (FDA) set strict standards for manufacturing. Every part of the process, from raw materials to the finished product, must have accompanying documentation.

The Importance of Consistency and Repeatability

Precision machining is essential for meeting these regulatory demands. CNC machines can produce identical parts over and over again. This consistency is critical for validation and approval. Once a process is approved, the manufacturer must be able to repeat it without any deviation. A reliable machine ensures that the 10,000th medical device part is exactly the same as the first.

This is where the longevity and durability of a machine become vital. A machine that constantly needs repairs or adjustments cannot provide this level of consistency. Downtime in a medical manufacturing facility is not just an inconvenience. It can delay the supply of critical devices to hospitals and patients. Investing in robust, dependable machinery is the best way to ensure continuous, compliant production.

The Future of Medical Manufacturing

Technology continues to advance at a rapid pace. The medical sector is seeing a rise in miniaturization and complex geometries. Devices are becoming smaller, smarter, and more intricate. This includes everything from tiny sensors that monitor bodily functions to micro-instruments for minimally invasive surgery. These innovations push the boundaries of what is possible in manufacturing.

5-Axis Machining and Complex Parts

Creating these next-generation devices requires more advanced machining capabilities. 5-axis CNC machines are becoming the new standard. These machines can move a part or a cutting tool along five different axes at the same time. This allows for the creation of highly complex shapes in a single setup. It reduces the need to move the part between different machines, which improves accuracy and efficiency.

For example, a complex orthopedic implant might have curved surfaces and deep pockets. A 5-axis machine can create these features with exceptional precision. As medical technology evolves, the demand for advanced manufacturing processes will only grow. Having the right equipment is key to staying competitive and driving innovation.

Why Quality and Longevity Trump Price

When choosing a CNC machine, it can be tempting to focus on the upfront cost. However, we know that the true cost of a machine is something you measure over its entire lifespan. A cheaper machine may seem like a good deal initially, but if it breaks down frequently, it can cost a company far more in lost production and repair bills. In the medical sector, the stakes are even higher. A faulty machine can compromise the quality of parts used to save lives.

We believe in building machines that last. Our commitment to quality means using superior components and robust construction. This results in machines that offer outstanding rigidity and exceptional reliability. Their longevity provides a better return on investment and gives manufacturers peace of mind. Plus, our comprehensive service and support ensure that our partners get the most out of their investment—this commitment to quality is why so many trust the YCM Alliance’s precision machining solutions.

Your Partner in Excellence

The link between manufacturing excellence and patient care is undeniable. Every precise cut and every perfect component contributes to better medical outcomes. We have explored the many facets of precision machining’s importance in the medical sector. From creating intricate surgical tools to enabling customized implants, the impact is profound. Meeting stringent regulatory standards and working with difficult materials requires equipment of the highest caliber.

As medical technology continues to evolve, the need for advanced, reliable, and precise machines will only increase. Choosing a machine based on its quality, reliability, and longevity is not just a business decision; it is a commitment to patient safety and healthcare innovation.