YCM Alliance Adds Tongtai Turning Centers to its Lineup of Precision CNC Machining Solutions

Santa Fe Springs, Calif., October 16, 2025 — YCM Technology USA, Inc. (YCM Alliance) is proud to announce that Tongtai Machine & Tool Co., Ltd. (TT) (Stock Code: 4526), a leading manufacturer of high-quality CNC machining solutions in Taiwan (ISO 9001:2015), has joined the YCM Alliance. Under the agreement, the YCM Alliance serves as the exclusive importer and marketing organization for TT horizontal CNC turning centers throughout the United States. It can also market, promote, and sell the product line throughout Canada and Mexico.

“There has been long-standing admiration and respect between YCM and TT for designing and manufacturing precision, high-quality machine tools with a proven track record for reliability, precision, and repeatability,” according to Tony Pekalski, President of YCMT. “Adding TT turning solutions to the YCM Alliance fills a strategic need for our customers, one that we are very happy to fulfill given the reputation of the brand".

“There is excellent alignment between the YCM Alliance and the TT line of turning solutions, starting with high-quality and reliable machines that deliver customer-based solutions. But it doesn’t stop there. We are committed to the YCM Alliance layered service and support strategy, which involves the entire channel to serve the best interest of each customer,” said Arthur Deng, TT Sales and Service Operations.

Under the YCM layered service and support strategy, technical and service issues are quickly escalated for fast resolution. Starting with the dealer, service tickets that cannot be resolved immediately are submitted to the YCM Alliance field service team. This process effectively resolves 90% of all service and support requests, but if necessary, each YCM Alliance builder partner is also committed to ensuring customer success. Every link in the service and support chain works together to maximize uptime.

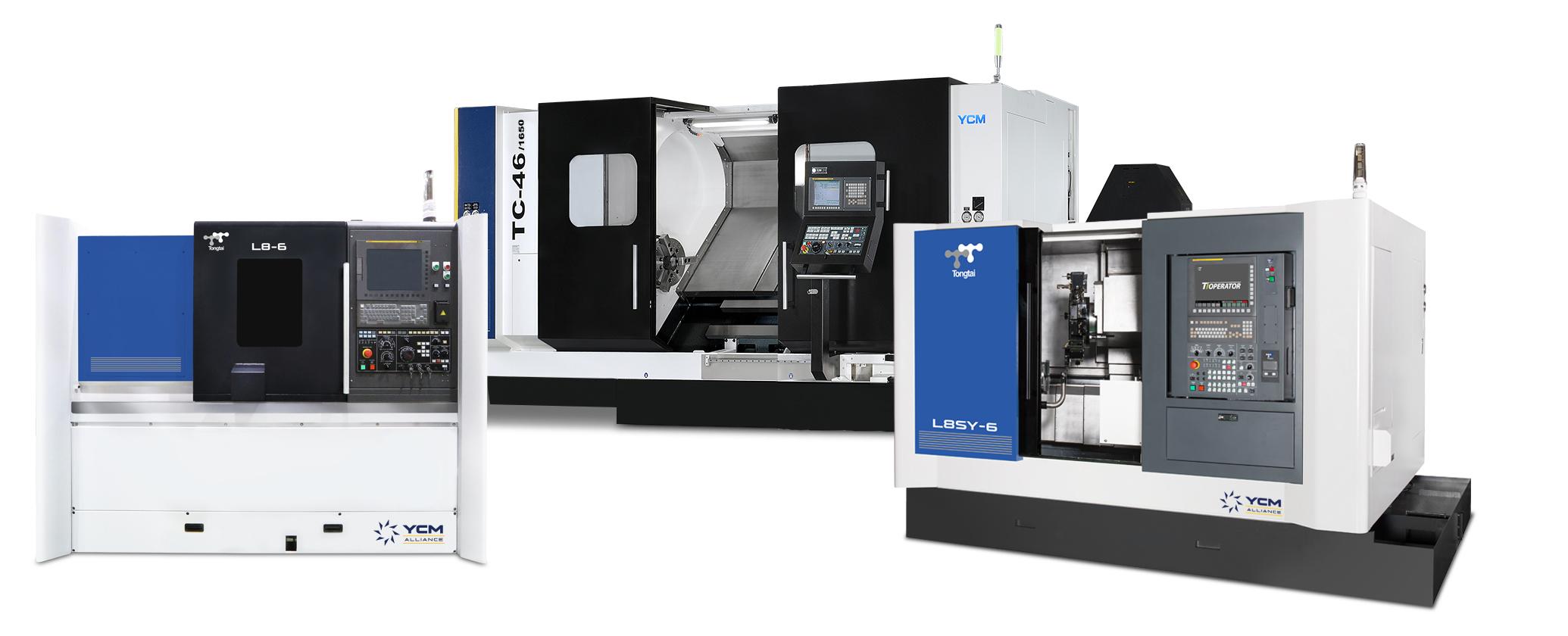

Complementing the existing YCM turning solutions, the new TT models include five horizontal CNC turning center series. With variable configurations, the lineup comprises 16 new turning center solutions, with additional models in development. Custom turn- key solutions are also available on request.

The TT L8 Series Turning Center Features Linear Roller Guideways, Fanuc 0iTF+, MGi, 15" w/iHMi, A2-6 Spindle Nose, 8” Chuck, 20/15 HP (15/11 kW) 4,500rpm, Belted, 2.01" (51mm) Bar Capacity, 12 Station Static Servo Turret, Manual Tailstock w/3.94" Quill Stroke, Parts Catcher, Rapids in X/Z - 1181 ipm. (30m/min), Auto Grease Lubrication, Auto Renishaw Tool Probe (HPMA), Air Gun, Coolant Gun, 80 psi. (5.51 bar) Coolant Pressure, 43.31” (1100mm) Height Chip Conveyor, 3-Color Warning Lamp, Dual LED Work Lights, Bar Feed Interface, Up to1000 psi (70 bar) HP Coolant Interface, 1-Set Soft Jaws, 1 MT#4 Rotating Center. It has a Swing Diameter of 20.47” (520mm), and X/Z Travel of 6.69”/23.62” (170mm/600mm).

The TT L8M Series Turning Center Features Linear Roller Guide-ways, Fanuc 0iTF+, MGi, 15" Screen w/iHMi, A2-6 Spindle Nose, 8” Chuck, 20/15 HP (15/11 kW) 4,500rpm, C-Axis .001 Deg., Belted, 2.01 (51mm) Bar Capacity, 12 Station Power Turret, BMT-65, Manual Tailstock w/3.94" Quill Stroke, Parts Catcher, Rapids in X/Z - 1181 ipm. (30m/min), Auto Grease Lubrication, Auto Renishaw Tool Probe (HPMA), Air Gun, Coolant Gun, 80 psi. (5.51 bar) Coolant Pressure, 43.31” (1100mm) Height Chip Conveyor, 3-Color Warning Lamp, Dual LED Work Lights, Bar Feed Interface, up to 1000 psi (70 bar) HP Coolant Interface, 1-Set Soft Jaws, 1-MT#4 Rotating Center, 2 Sets BMT-65 Axial (90 DEGREE) Live Tool Holder, 2 Sets BMT-65 Radial (Straight) Live Tool Holders. It has a Swing Diameter of 20.47 (520mm), and X/Z Travel of 7.87”/23.62” (200mm/600mm).

The TT L8SY Series Turning Center Features Linear Roller Guide-ways, Fanuc 0iTF+, MGi, 15" w/iHMi, A2-8, 8” Chuck, 25/20/15 HP, (18.5/15 /11 kW) 4,500rpm, C-Axis .001 Deg., Belted Main Spindle, 2.52" (64mm) Bar Capacity, Built-in Type Sub Spindle, A2-5, 8” Chuck, 10/7.4HP, 5000rpm, C-Axis .001 Deg., 1.02" (26mm) Bar Capacity, 12 Station (or 16 Station with BMT-55) Power Turret, BMT-65, Sub Parts Catcher, Rapids in X/Z/B - 1,181 ipm. (30m/min), Rapids in Y-Axis - 590 ipm (15m/min), Auto Grease Lubrication, Auto Renishaw Tool Probe (HPMA), Air Gun, Coolant Gun, 80 psi. (5.51 bar), Coolant Pressure, 43.31” (1100mm) Height Chip Conveyor, 3-Color Warning Lamp, Dual LED Work Lights, Bar Feed Interface, up to 1000 psi (70 bar) HP Coolant Interface, 1-Set Soft Jaws, 2 Sets BMT-65 Axial (90 Degree) Live Tool Holder, 2 Sets BMT-65 Radial (Straight) Live Tool Holders. It has a Swing Diameter of 27.56” (700mm), and X/Y/Z/B Travel of 9.06”/±2.01”/23.62”/24.8” (230mm ±51mm/600mm/630mm). The X/Y/Z Axes are Orthogonal to One Another, Providing Straightness and Precise Positioning for Both Turning and Milling Applications.

The TT L10SY Series Turning Center Features Linear Roller Guide-ways, Fanuc 0iTF+, MGi, 15" w/iHMi, A2-8 Spindle Nose, 10” Chuck, 25/20/15 HP (18.5/15 /11 kW), 3,500rpm, C-Axis .001 Deg., Belted Main Spindle, 3.19" (81mm) Bar Capacity, Built-in Type Sub Spindle, A2-5 Spindle Nose, 8 Chuck, 10/7.4 HP, 5000rpm, C-Axis .001 Deg., 1.02" (26mm) Bar Capacity, 12 Station Power Turret, BMT-65, Sub Parts Catcher, Rapids in X/Z/B - 1,181 ipm., (30m/min) Rapids in Y-Axis - 590 ipm (15m/min), Auto Grease Lubrication, Auto Renishaw Tool Probe (HPMA), Air Gun, Coolant Gun, 80 psi (5.51 bar) Coolant Pressure, 43.31” (1100mm) Height Chip Conveyor, 3-Color Warning Lamp, Dual LED Work Lights, Bar Feed Interface, up to 1000 psi (70 bar) HP Coolant Interface, 2-Set Soft Jaws, 2 Sets BMT-65 Axial (90 Degree) Live Tool Holders, 2 Sets BMT-65 Radial (Straight) Live Tool Holders. It has a Swing Diameter of 27.56” (700mm), and X/Y/Z/B Travel of 9.06”/±2.01”/23.62”/24.8” (230mm ±51mm/600mm/630mm). The X/Y/Z Axes are Orthogonal to One Another, Providing Straightness and Precise Positioning for Both Turning and Milling Applications.

The TT B15Y Series Turning Center Features a Box Way Design with Fanuc 0iTF+, MGi, 15" Screen w/iHMi, A2-11 Spindle Nose, 15” Chuck, 60/50/40 HP (45/37/30kW), 2000rpm, C-Axis .001 Deg., Belted Spindle with External 1:4 Gearbox, 4.57" (116mm) Bar Capacity, 12 Station Power Turret, BMT 75, Rapids in X/Z - 787 ipm. (20m/min), Rapids in Y-Axis - 393 ipm. (10m/min), MT#5 Programmable Tailstock w/Quill Stroke of 5.91, Auto Oil Lubrication, Coolant Skimmer, Auto Renishaw Tool Probe (HPMA), Air Gun, Coolant Gun, 80 psi. (5.51 bar) Coolant Pressure, 43.31” (1100mm) Height Chip Conveyor, 3-Color Warning Lamp, Dual LED Work Lights, Bar Feed Interface, up to 1000 psi (70 bar) HP Coolant Interface, 1-Set Soft Jaws, 2 Sets BMT-75 Axial (90 Degree) Live Tool Holders, and 2 Sets BMT-75 Radial (Straight) Live Tool Holders. It has a Swing Diameter of 24.41” (620mm) and X/Y/Z Travel of 14.37”/±2.95”/78.74” (365/±75/2,000).

Titans of CNC Boombastic

The TT L8M-6 and TT L8SY-6(12T) turning centers will be on display with cutting demonstrations at the upcoming Boombastic event hosted by the Titans of CNC, November 13-14, Dallas, Texas. For more information or to register to attend Boombastic, visit the YCM Alliance Events Page. Following Boombastic, TT turning solutions will be available for demonstration at the YCM Alliance Technical Centers located in Michigan, Texas, and California.

Since 1954, YCM CNC Machine Tool has established a legacy of producing world-class CNC machines renowned for their superior precision, rigidity, and dependability. ISO 9001 and ISO 14001 certified, YCM offers more than 70 models that serve a diverse range of industries. Through the YCM Alliance, this dedication to quality is extended. The YCM Alliance unites premium machine tool brands and application experts to deliver best-in-class machining solutions and support. With a shared commitment to innovation and customer success, the Alliance partners work collaboratively to meet the evolving needs of manufacturers.